Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: XL-FD330

Brand: XINLEI

Applicable Industry: Hotels, Garment Shops, Machinery Repair Shops, Food &Amp; Beverage Factory, Restaurant, Home Use, Food Shop, Food &Amp; Beverage Shops, Other

Out-of-warranty Service: Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Germany, Pakistan, Malaysia, Uae, Kazakhstan, Ukraine, Colombia, Australia, Viet Nam, India, Canada, Turkey, Philippines, Morocco, Mexico, Algeria, Kyrgyzstan, Sri Lanka, Russia, United Kingdom, Brazil, Kenya, Nigeria, Uzbekistan, Romania, Argentina, Spain, Peru, United States, Italy, Saudi Arabia, Thailand, South Korea, Bangladesh, Japan, France, Indonesia, Chile, South Africa, Tajikistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Germany, Pakistan, Kenya, Sri Lanka, Kyrgyzstan, Nigeria, Romania, Argentina, India, Viet Nam, Canada, Turkey, Philippines, Mexico, South Korea, Bangladesh, Uzbekistan, Tajikistan, South Africa, Chile, Russia, Brazil, United Kingdom, United States, Peru, Spain, Uae, Kazakhstan, Japan, Thailand, Saudi Arabia, Italy, France, Indonesia, Morocco, Algeria, Colombia, Ukraine, Malaysia, Australia

Status: New

Product Category: Paper Bag Making Machine

Processing Type: Cutting Machine

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Productivity: 200 Pcs/Min

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

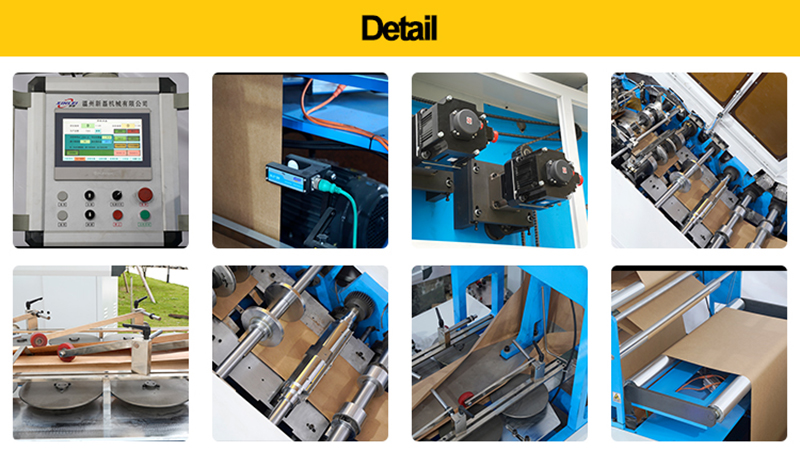

Core Components: Plc, Motor, Gear

Transportation: Ocean

Place of Origin: WENZHOU

Port: ningbo

Payment Type: T/T

Incoterm: FOB

| Model | XL-FD330(W+D) |

| Cutting Length | 270-530mm |

| Paper Bag Width | 120-330mm |

| Holation width | 50-120mm |

| Holation height | 50-120mm |

| Bag bottom width | 60-180mm |

| Pky bag width | 190-330mm |

| Pky Bag Wrist hole | 75/85mm |

| Paper thickness of the patch bag | 80-150g/㎡ |

| Pky bag film thickness | 30-60um |

| Pky bag roll Widwidth | 130mm |

| Piky Bag Paper Bag Speed | 30-120pcs/min |

| Mechanical speed | 30-200pcs/min |

| Paper bag speed | 30-150pcs/min |

| Paper roll width | 380-1050mm |

| Bar window Size | 60-150mm |

| Paper Material Diameter | 1200mm |

| Complete power | 380v 3phase 4line 50.4kw |

| Operating Machine Weight | 10000kg |

| Complete machine size | 15500*4200*2000mm |

Q:Are you factory or trading company?

A: We are factory and manufacture.

Q:The Lead time about one set?

A:about 30- 35 days

Q:How about production speed?

A:30-220 pcs/min according to different type of the paper bag

Q:How many workers need to operate the equipment?

A:need only 1 worker to operate

Product Categories : Paper Bag Making Machine > Automatic Paper Bag Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.